Thermal Interface Materials

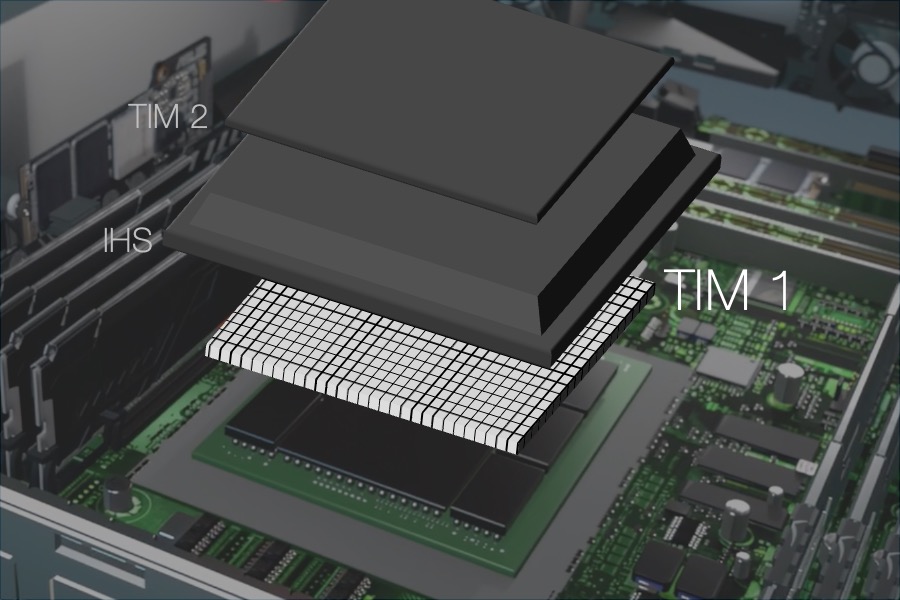

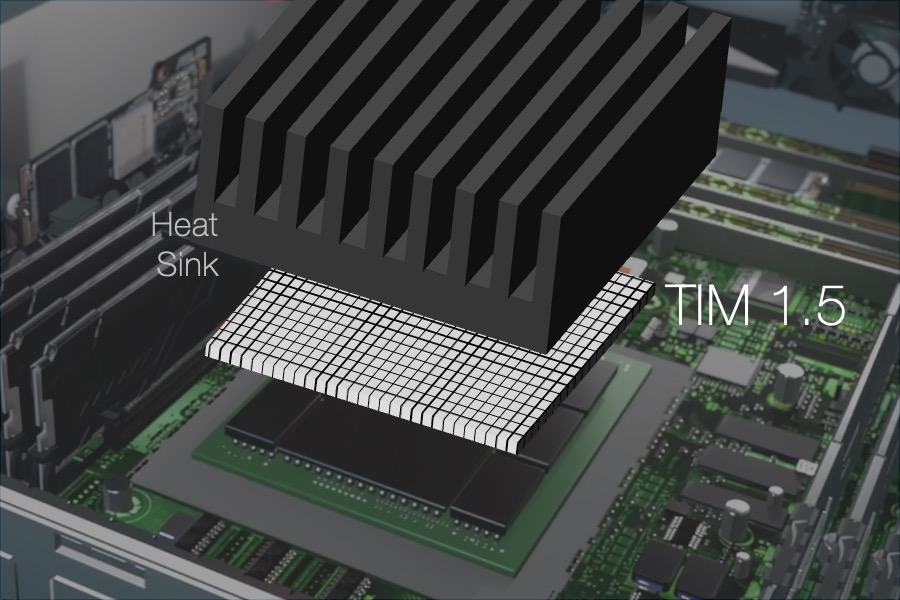

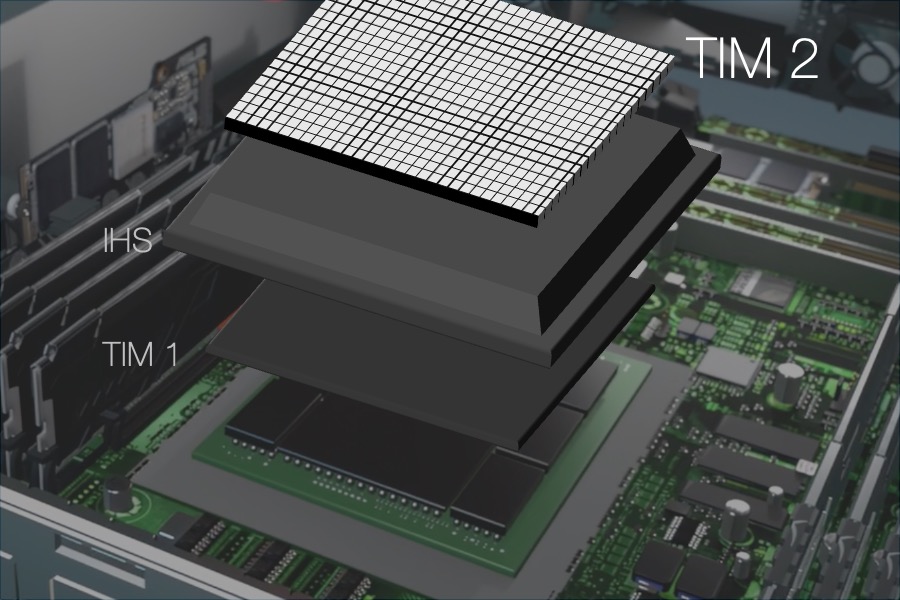

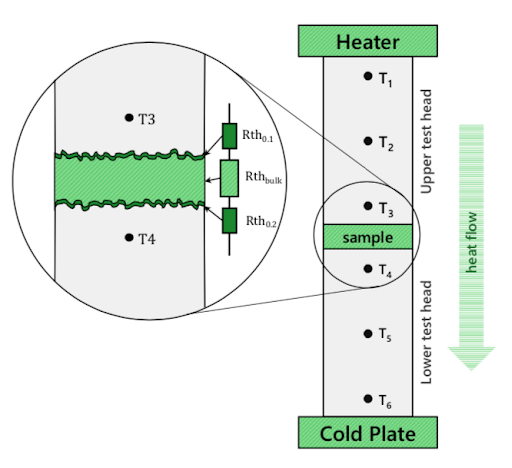

There Is More to Thermal Management than Thermal Conductivity

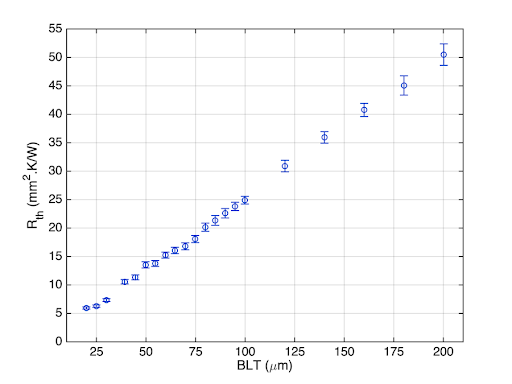

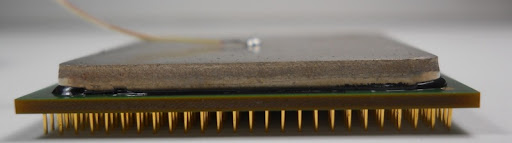

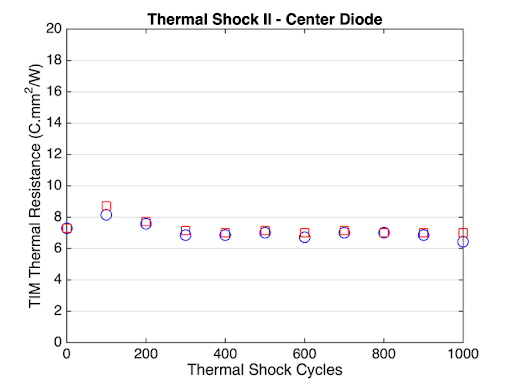

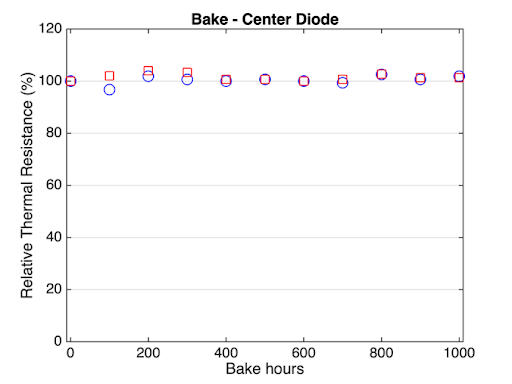

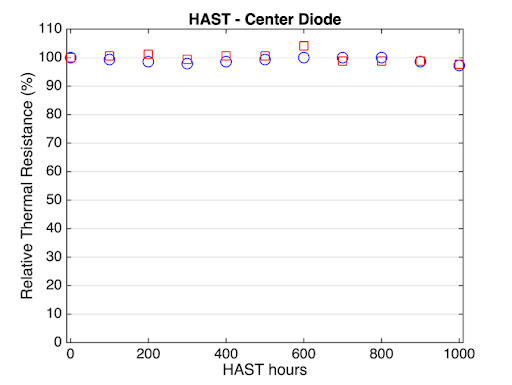

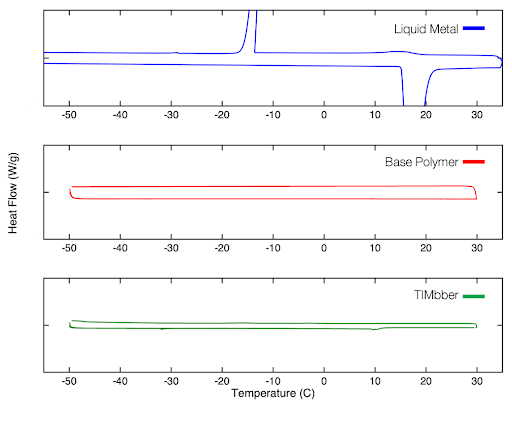

Traditional solder-based metals are commonly used in semiconductor applications. However, due to their rigidity and lack of conformance, they require a large bond line and complicated assembly. Arieca’s high elongation, conforming LMEE brings thin bond line liquid metal TIMs to standard HVM flows without sacrificing reliability.