Liquid Metal Embedded Elastormers

Redefining fundamental trade-offs

LMEE breaks the fundamental trade-off between elasticity and thermal conductivity, opening up a whole new range of material possibilities.

Liquid Metal Embedded Elastormers

LMEE breaks the fundamental trade-off between elasticity and thermal conductivity, opening up a whole new range of material possibilities.

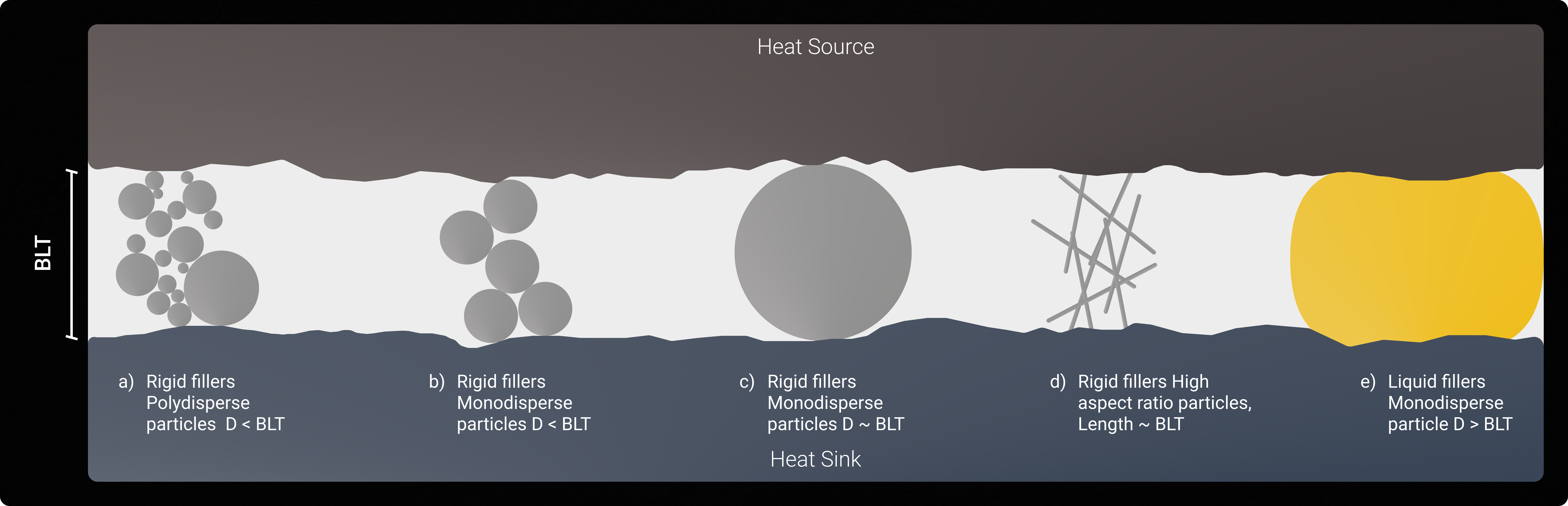

Contact resistance arising from particle-to-particle and particle-to-surface resistances is the major contributing factor for high interfacial contact resistance in traditional P-TIMs. Liquid Metal fillers dramatically change this. Additionally, highly deformable liquid filers allow extremely low bond-line thicknesses achievable.

Liquid metals as fillers dramatically change the way polymer-filled TIMs transfer heat between interfaces by establishing extremely low contact resistance enabling low bond-line thicknesses.

The result is a breakthrough multi-functional LMEE composite material that breaks the long-standing trade off that high thermal and electrical functionality is achievable only in stiff, brittle and inflexible material. LMEEs are capable of: